“TMT is very excited that the Coherent production team is so active and efficient,” says Ben Gallagher, leader of TMT’s Telescope Optics group. “The production is ramping up and we anticipate getting close to 50 additional roundels manufactured in California in 2022!”

Each roundel is being produced in accordance to strict technical specifications, and meeting these requirements is critical to the success of the TMT Observatory. To ensure that each segment will perform satisfactorily, optical interferometers are used to closely analyze and control the roundels, and to verify the quality of their polished surfaces. All interferometric metrology data from Coherent were reviewed using independent analysis at NASA's Jet Propulsion Laboratory (JPL), which is partnering with TMT. A variety of analyses successfully met JPL’s chart of performance metrics. The surface measurement table from Coherent met and even exceeded the TMT’s expectations.

“Indeed, we are thrilled and confident about the roundels’ quality,” says Glen Cole, TMT lead Optical Fabrication engineer, while visiting the Coherent production facility in the Bay area last December. “Being out there and looking directly at the improvements made to optimize the efficiency of all processes is very impressive.”

In addition to inspecting the delivered roundels, Cole was also co-training at an extended coaching session provided for the India TMT Coordination Centre’s (ITCC) optical engineers.

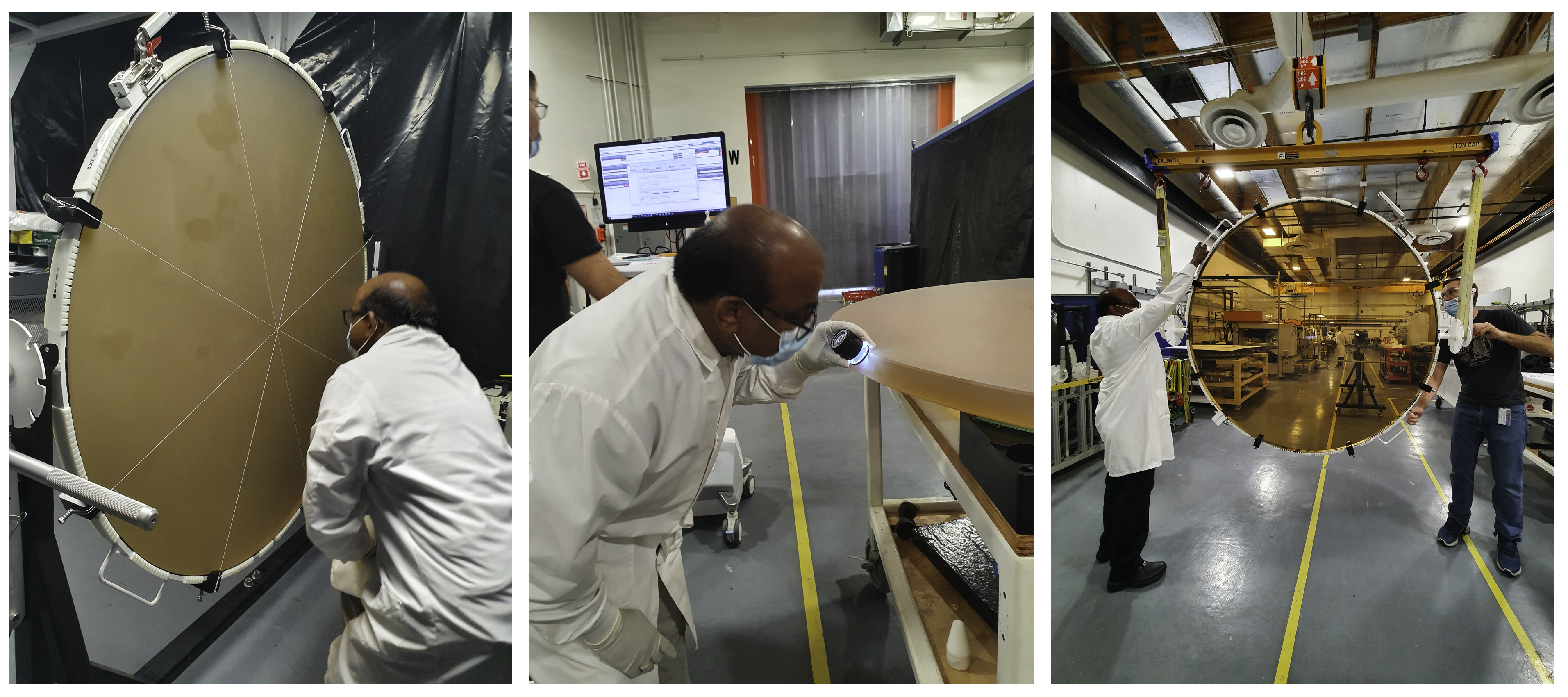

As soon as Covid-19 travel restrictions were lifted, two TMT India engineers flew to California for a training on producing TMT’s aspherical polished roundels using the Stress Mirror Polishing technology. During this instructional phase, which is taking place independently of Coherent’s mirror production, Coherent engineers are providing hands-on coaching sessions on the operations of the specific tools and equipment that ITCC engineers will use in their newly built India-TMT Optics Fabrication Facility (ITOFF)1. The coaching also includes instruction on the qualification tests performed during roundel production. In the coming months, a third person will come from India for a second phase of training.

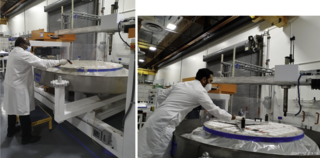

Coherent’s hands-on training in December 2021 - On-site support and training program held at Coherent facility - Glen Cole, S. Sriram and Alikhan Basheer take part in the learning program about the mirror polishing, in which mirror blanks are converted into roundels meeting all necessary requirements - Image credit: TMT International Observatory / ITCC

“Coherent is honored to host our guests from India and share our expertise in Stress Mirror Polishing technology,” says Lou Marchetti, Development Engineer at Coherent leading the polishing training effort. “We look forward to having that team join us in polishing these mirrors to perfection.”

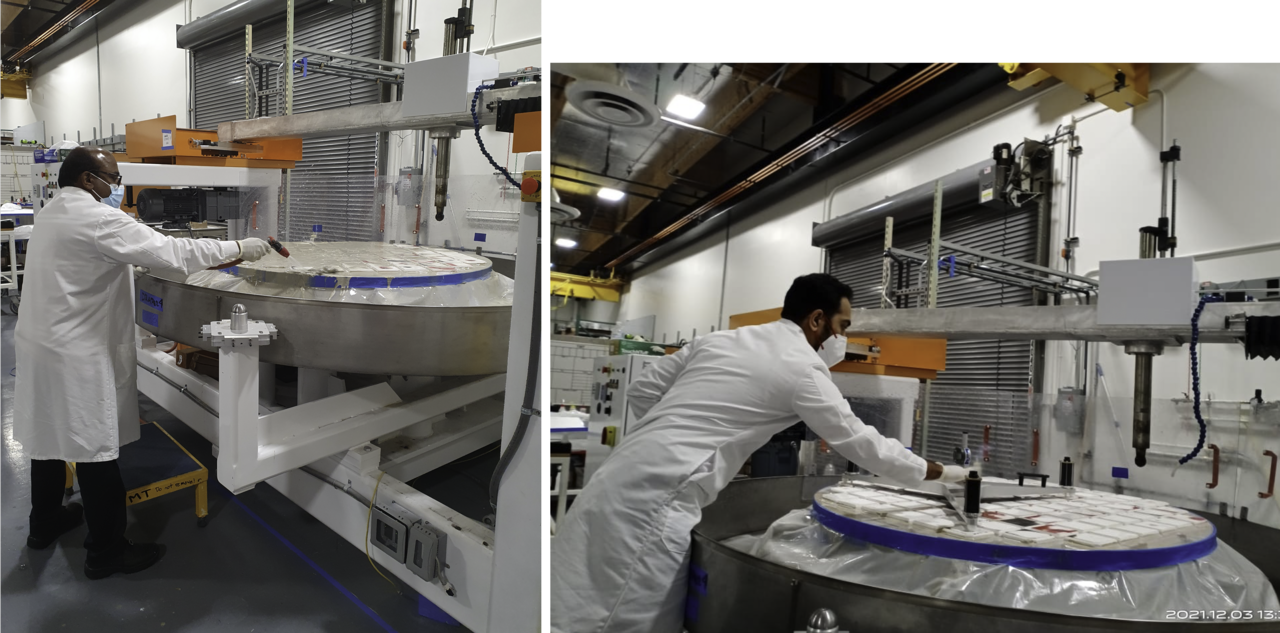

Coherent training on Stressed Mirror Polishing technology, December 2021 - Engineers apply cutting-edge technology to all aspects of operations and production - Image credit: TMT International Observatory / ITCC

“This past year has been very good in terms of production, and also for the comprehensive training work and the best practices involved in precise mirror polishing,” added Cole. “We have seen excellent cooperation between TIO and Coherent.”

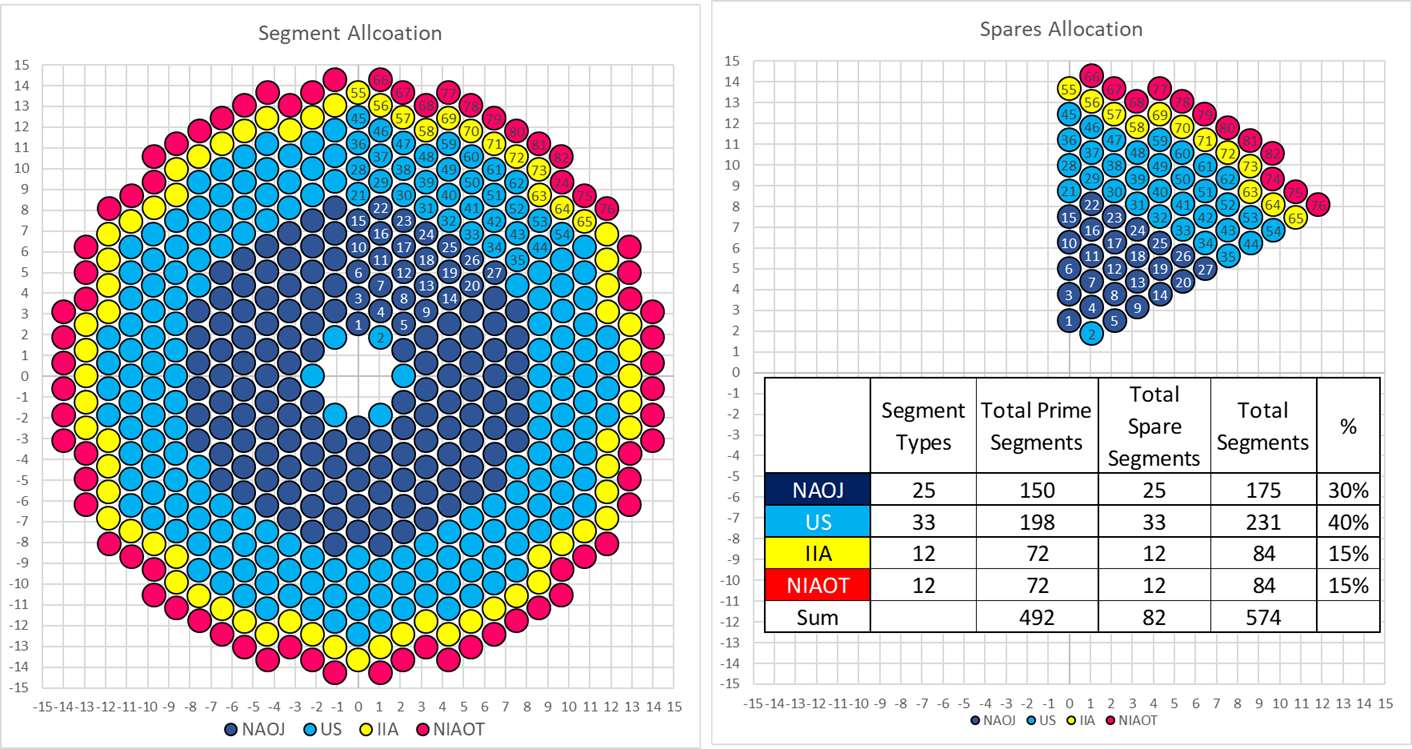

TMT M1 Segment allocation – December 2021 - TMT mirror blanks, made of the zero-expansion glass ceramic Clearceram-z by NAOJ /TMT Japan, are being distributed among the four partner countries (Japan, US, India and China) for the surface polishing process - Image credit: TMT International Observatory

ITCC has developed a dedicated polishing facility (ITOFF), inaugurated near Bengaluru in 2021, that will enable India-TMT to more efficiently handle the polishing and testing of its 84 primary segments. Following the current training, Coherent will ship a set of production equipment that was purchased by IIA to support their production in ITOFF. TMT’s Indian partners will soon convert TMT’s Clearceram-z mirror blanks from OHARA/NAOJ in Japan into high-quality surface hexagonal mirror segments.